Startseite / Software / PowerShape / PowerShape Standard

Die Funktionen zur Modellierung von Volumenmodellen in PowerShape Standard ermöglichen die Erstellung eines auf der Merkmalshistorie basierenden, zuverlässigen Projekts auf schnelle und einfache Weise.

Die Volumenmodellierung ermöglicht die einfache Definition und Bearbeitung von:

- Kugeln,

- Quadern,

- Zylindern,

- Tori,

- Kegeln.

PowerShape Standard ermöglicht das Importieren von Dateien in neutralen CAD-Formaten (z. B. IGES, STEP) sowie das automatische Auffinden und Reparieren von Defekten, die den weiteren Produktionsprozess erschweren könnten. Mit PowerShape lassen sich Hinterschnitte, kleine Radien und dünne Wände erkennen und eine direkte Modellierung durchführen, um Teile für die Produktion vorzubereiten.

PowerShape unterstützt solides Design. Zusätzlich zur Solid-Modelling-Funktion enthält es:

1. Boolesche Operationen – Verbindet die Vorteile der Volumen- und Flächenmodellierung, um schnell komplexe Formen zu erstellen

2. Solid Doctor – Importierte Daten aus jedem CAD-System können repariert werden, so dass sich ein fehlerfreies Volumenmodell erstellen lässt. Dies ermöglicht unter anderem:

- Rekonstruktion fehlender oder beschädigter Oberflächen,

- Flicken von Löchern und Rissen,

- Entfernen doppelter Flächen,

- Einschneidende Fehler reparieren.

3. Direct Modelling – Komplexe Änderungen schnell und einfach durchführen – sogar an impotierter CAD-Geometrien ohne Merkmalsgeschichte. Diese Funktion ermöglicht unter anderem das Ändern von Größe oder Form von Rundungen, Taschen usw. Es ermöglicht, Oberflächen / Merkmale zu ändern durch:

- Verschiebung,

- Offset,

- Drehung,

- Skalierung,

- Aufteilung,

- Ersetzen der Oberfläche.

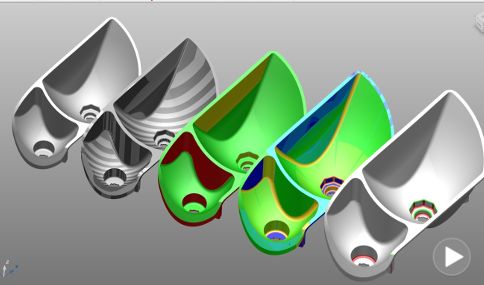

4. Visuelle Analyse eines Modells – Mithilfe leistungsstarker interaktiver Modellanalyse-Werkzeuge können potentielle Fertigungsprobleme erkannt werden, bevor mit der Bearbeitung begonnen wird. Diese Funktion ermöglicht:

- Erkennen dünner Wände und kleiner Radien, die spezielle Maschinenbedienung erfordern,

- Verbindung von Flächen, m die Fertigung zu vereinfachen,

- Erstellen multi-axialer Referenzflächen.

Darüber hinaus verfügt PowerShape Standard über effiziente Werkzeuge, mit deren Hilfe erforderliche Änderungen schnell und einfach durchgeführt werden können, einschließlich:

- Erstellen oder Ändern von Verrundungen, um die Bearbeitung zu vereinfachen,

- Hinzufügen von Entform-Winkeln, um Teile nach dem Formen leichter auswerfen zu können,

- Erstellung komplexer Teilungs- und Entformflächen.

Die Oberflächenmodellierung in PowerShape ermöglicht die schnelle und einfache Erstellung zuverlässiger Modelle.

Die Funktion Flächenmodellierung ermöglicht das einfache Erzeugen und Bearbeiten von:

- Flächen,

- Kugeln,

- Zylinder,

- Torus,

- Kegel,

- Federn.

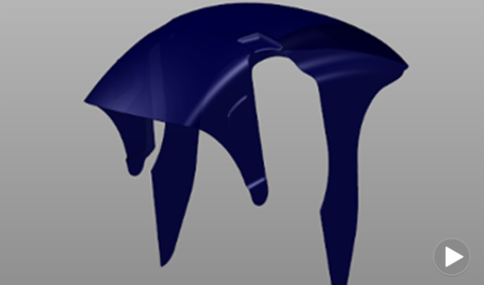

Produkt- und Industriedesign

Mit schnellen Skizzierwerkzeugen können genaue Kurven schnell und einfach erstellt werden, um Flächenformen zu entwickeln. Mithilfe interaktiver Morphwerkzeuge können Designvarianten erstellt werden, indem Modelle gebogen, verdreht oder verformt werden. Mithilfe einfach zu handhabender Flächenbearbeitungswerkzeuge können Formen bereits während der Ideenfindung abgeändert werden. Flächen, Volumenmodelle und Baugruppen werden passgenau kombiniert, um ein Designwerkzeug anzubieten, welches Teile erstellt, die nicht nur ästhetisch wertvoll sondern auch funktional und einfach zu fertigen sind. Mithilfe leistungsstarker Werkzeuge zum Aufwickeln können komplexen Freiformen dekorative Texturen hinzugefügt werden, um so Designs zu erstellen, die auf anderem Weg nicht gefertigt werden könnten. PowerShape verleiht völlige Freiheit bei der Erzeugung aller erdenklicher Formen.

Verpackung

Verpackungsdesiner sind auf der ständigen Suche nach noch innovativeren und attraktiveren Wegen, um die Produkte ihrer Kunden zu präsentieren. Die schnellen und genauen Flächenmodellierungswerkzeuge von PowerShape verleihen völlige Freiheit bei der Erstellung der spannendsten Formen und einer schnellen Umsetzung von Design-Ideen. Mit dem einzigartigen `Auf Volumen skalieren´-Werkzeug von PowerShape sieht das Design garantiert nicht nur gut aus, sondern kann auch die korrekten Produktmengen fassen und wirtschaftlich fertigen.

Flexible Flächenmodellierung in PowerShape bedeutet vor allem:

- „Smart Surfacer“ – dank ihm wird Flächenmodellierung zum Kinderspiel, indem der sinnvollste Flächentyp automatisch – basierend auf den markierten Kurven – ausgewählt wird,

- Intuitive Editier-Werkzeuge – Änderungen beliebiger Flächen sind jederzeit möglich,

- Erweiterte Funktionen zur Kontaktsteuerung,

- Kurven und Punkte der Oberfläche verändern und manipulieren,

- Flächen verbinden und teilen,

- Möglichkeit, Volumenkörper in Oberflächen umzuwandeln und umgekehrt,

- Verwendung der Volumenmodellierungsoperationen für die einfache Erstellung ästhetischer und zugleich funktionaler Modelle.

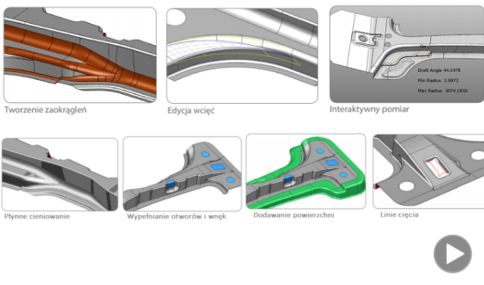

Mit der Formenkonstruktion in PowerShape stehen dem Formenkonstrukteur zahlreiche spezifische Funktionen zur Verfügung, die den zeitaufwändigen Prozess des Zusammenbaus einer Konstruktion erheblich verkürzen und die Produktqualität verbessern.

1. Leistungsstarke Verrundungswerkzeuge

Leistungsstarke und dennoch leicht zu bedienende Verrundungsfunktionen helfen beim Erstellen perfekter Verrundungen von Flächen, vereinfachen das Materialflussverhalten und erhöhen die Bauteilqualität. Die Verrundungsfunktionen beinhalten u. a. :

- Mehrfach-Flächenverrunden,

- Konstanter oder variabler Radius,

- Automatisches Trimmen der umliegenden Flächen,

- Interaktives Aufnehmen von Verrundungswegen.

2. Flächen modifizieren

Hochmoderne Modellierungswerkzeuge helfen, die optimale Form in kürzest möglicher Zeit zu erstellen. Flächen modifizieren bedeutet:

- Interaktives Ändern von Trimmgrenzen,

- Tangentenstetiges Verlängern von Flächen,

- Interaktives Glätten und Verformen von Flächen,

- Morphen von Flächen: Modifizieren der Form mehrerer Flächen bzw. ganzer Modellbereiche und Flächenmodelle.

3. Bauteilmerkmale

Diese Funktion ermöglicht:

- Dynamisches Erfassen von Bauteilmerkmalen direkt am Bildschirm,

- Wichtige Modellmerkmale schnell und präzise hervorheben,

- Effektive Erstellung von Detailplänen,

- Entformungswinkel und kritische Radien direkt aus Volumenmodellen oder Flächen ableiten,

- Mit Hilfe des dynamischen Schnitts wird die Größe des mit dem Presswerkzeug herzustellenden Produkte ermittelnt.

4. Analyse der Flächenqualität

Stellen Sie sich das Bauteil als eine Art Landkarte vor, auf der Mängel hervorgehoben werden. Verwenden Sie Flächenmodellierungswerkzeuge, um diese Mängel zu beheben und Zeitverzögerungen im Fertigungsprozess zu vermeiden. Darüber hinaus:

- passen Sie die Teilausrichtung an, um Hinterschnitte zu beseitigen,

- finden Sie kleinste Radien auf Stempel und Matritze, welche Fertigungsprobleme verursachen könnten.

5. Füllflächen

Findet Bohrungen und Aussparungen und deckt diese mit tangential zusammenhängenden Füllflächen ab, um die Fertigung zu vereinfachen. Aussparungen rund um den Rand des Bauteils können schnell identifiziert und Ergänzungsflächen zum Schließen der Flächenspalten einfach erstellt werden.

6. Ergänzungsflächen

Ergänzungsflächen, die für einen glatteren Materialfluss sorgen sollen, werden direkt aus vorhandenen Flächen erstellt.

7. Ziehleisten

Um das Verschieben des Materials während des Pressvorgangs zu vermeiden, werden Ziehleisten und Ziehwulste af Stempel und Matritze angebracht. Erstellen Sie diese Flächen durch das Selektieren von Teilen der Trennlinie oder indem Sie diese selbst erstellen.

8. Trennlinien

Für Anwendungen, die Stanz- und Gesenkformen benötigen, wird die Trennlinie des Produktmodells automatisch erkannt und zwei Formblöcke geeigneter Größe werden vorgeschlagen. Anschließend werden Trenn- und Abgratflächen erstellt, um die beiden Formhälften zu bilden. Die Formeinsätze werden dynamisch mit den Trennflächen von den Formblöcken getrennt.

Die „Rippendeckflächen“-Funktion in PowerShape erstellt automatisch Oberflächen zum abdecken komplexer Rippenfeatures.

PowerShape wurde konzipiert, um PowerMill und FeatureCAM zu ergänzen und so erforderliche Änderungen im Fertigungsprozess durchzuführen, ohne Bearbeitungsvorgänge zu unterbrechen. PowerShape hilft dabei, Geometrien zu erzeugen, die für beste Ergebnisse der CNC-Maschinenarbeit erforderlich sind. Bearbeitungsbegrenzende Bereiche werden definiert, ein Netzwerk von Flächen wird angelegt, um enge Bereiche in Rippenform abzudecken. Mithilfe des ‚Rippendeckflächen‘-Werkzeugs können extrem komplexe Bereiche voll automatisch abgesperrt werden. Dadurch entsteht eine glattere Form, die einfacher zu bearbeiten ist und für eine verbesserte Steuerung von 5-Achsen-Maschinenbewegungen sorgt.

Die `Rippendeckflächen´-Funktionen sind:

- Automatisches Abdecken komplexer Rippenfeatures, um so die Fertigung von Formen und Werkzeugen zu beschleunigen,

- Erstellung aller benötigten Flächen mit nur einem einzigen Mausklick,

- Die Geometrie kann in PowerMill verwendet, um die Bearbeitung zu korrigieren,

- Tangentialflächen können an CAM-Software exportiert werden, um Werkzeuge zu schützen,

- Besseren Qualität der bearbeiteten Kanten und Reduzierung der Zykluszeit.