Startseite / Software/ FeatureCAM / FeatureCAM Premium

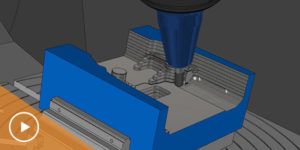

Mit der Kollisionsvermeidungsfunktion im FeatureCAM können sichere, kollisionsfreie Werkzeugwege erstellt und die Bearbeitung visualisiert werden, um so deren Korrektheit zu überprüfen.

FeatureCAM bietet Simulationsoptionen wie die Ansicht einer Symmetrieachse, 2D- und 3D-Simulationen, schnelle und Positionierbewegungen, den Vergleich von Bauteilen sowie die vollständige Prüfung von Kollisionsgefahren mit Maschinenelementen.

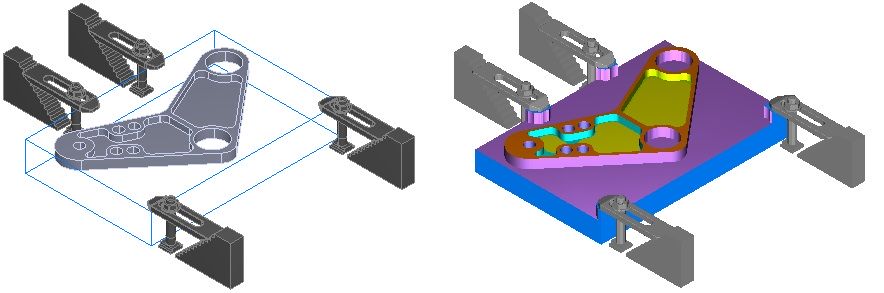

FeatureCAM ermöglicht die Generierung von Werkzeugbahnen mit automatischer Erkennung und Vermeidung der Werkzeughaltevorrichtungen. Um ein Element als Klemme oder Halter zu bestimmen, müssen Sie nur den Befehl „Körper als Halterung verwenden“ wählen. Die Software bietet die Möglichkeit, den Mindestabstand zur Halterung einzugeben.

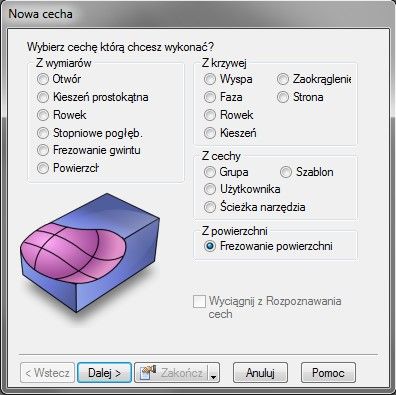

Feature Recognition ist ein Modul, das die automatische Erkennung von Features in Volumenkörpermodellen und die automatische Generierung von Bearbeitungsprozessen ermöglicht. Sie ermöglicht auch die Umwandlung einer Volumenkörpermodellkanten in Kurven oder die Erstellung einer Kurve aus dem Rotationsprofil. FeatureRrecognition bietet in seiner Standardversion die Möglichkeit, folgende Dateiformate zu importieren:

- SolidWorks (native 3D-Modelle)

- Inventor (native 3D-Modelle)

- Solid Edge (native 3D-Modelle)

- Parasolid

- IGES

- ACIS

- DXF

- DWG

Alle FeatureCAM-Funktionalitäten helfen dabei, die Programmierung von Teilen zu beschleunigen und somit die Ausgabe zu erhöhen. Feature Recognition automatisiert den gesamten Prozess und ist eine effiziente Lösung vom Import eines CAD-Modells bis hin zum auf Ihrer CNC-Maschine fertigen Bauteil.

2.5D-Fräsen ist die Grundfunktion in FeatureCAM. Es enthält die gesamte Leistung und den Bedienkomfort, die der essentielle Bestandteil von jedem FeatureCAM Produkt sind: Erweitertes 2.5D Fräsen, indexiertes 4-Achs-Fräsen und -Drehen sowie gravieren. Es erlaubt das Einlesen von IGES / DXF / DWG-Formaten. Darüber hinaus ermöglicht es die Vorschuboptimierung und die erweiterte Überprüfung von 3D-Simulation. Ändern Sie Features durch Neigen der Wände, Anfasen von Kanten oder Einfügen von Runden unter Anwendung von Flach-, Kugel- und Torus-Werkzeugen. Darüber hinaus ist es möglich, Vorlagen für lineare, kreisförmige, rechteckige und Punktoperationen zu erstellen.

Vorteile:

- Import von industriellen Standardformaten, wie IGES, DWG und DXF – für eine einfache Kommunikation mit Kunden.

- Schnelle und einfache Erstellung von zuverlässigen Werkzeugwegen dank Schritt-für-Schritt-Assistenten – Zeitersparnis.

- Anbindung einzelner Unterprogramme an die für viele Werkstücke vorgesehenen Programme – Minimierung der Programmierzeiten.

- Unterstützung der Serienbearbeitung für vertikale und horizontale Maschinen – ermöglicht die Bearbeitung vieler Teile unter einer Einstellung.

- Große Subprozessorbibliothek, um den Start der Arbeiten an einer Werkzeugmaschine zu beschleunigen.

2.5D Fräsen umfasst unter anderem folgende Funktionen:

- Löcher – gerade, Senker, Spotter, Stufenbohrer, gerade getapft, Stufengewinde

- Taschen – unbegrenzte Anzahl von Taschen mit variabler Tiefe

- Nuten – Gravur, innen, außen, auf XY-Ebene

- Inseln – unbegrenzte Anzahl von Inseln mit variabler Höhe

- Gewindefräsen – Innen- und Außengewinde

Verfügbare Fräs- und Bohrfunktionen:

- Kompensation von Werkzeugpunkten für Schrupp- und Schlichtwerkzeuge

- Mehrere Schrupp- und Schlicht-Bearbeitungsdurchmesser zur schnelleren Fertigstellung eines Features

- Aufmaß auf einem Boden belassen für die Nachbearbeitung

- Schruppbearbeitung

- Mehrfachbearbeitung von Bereichen mit Einschränkung für Luftfräsen

- Verschiedene Schruppwerkzeuge (von groß bis klein) für schnelleres Zerspanen großer Materialmengen

- Benutzerdefinierte Werkzeughalter

- Optimierte Werkzeugwechsel und Minimierung schneller Bewegungen

- Verwaltung von Werkzeugstandzeiten

- Bearbeitungstoleranzen einstellen

- Externe und eigene Bohr- und Fräsmakros

- Aufteilen des Programms in Stufen

- Auswahl an Werkzeugwegoptionen

- Trachoidaler Werkzeugweg für gerade Spalten und Nuten

- Gleich- und Gegenfräsen

- Materialeintrag – Punktbohren, schraubenförmig, Zick-Zack

- Punktbohren

- Bohrlöcher-Pilot

- Annäherung der Werkzeugwege durch Kurven und durch gerade Abschnitte

- Mehrere Durchgänge für eine bessere Oberflächenqualität

- Kompensation des Endbearbeitungspunktes

- Abschätzung der Bearbeitungszeit – Operationen und die Gesamtzeit

- Arbeiten in metrischen und Zollsystemen – metrische und Zoll-Bemaßungswerkzeuge

2.5D-Fräsen wird häufig bei der Herstellung von prismatischen Teilen verwendet, bspw. bei Automobil- oder Flugzeugteilen, bei denen Taschen oder Profile vertikale Wände haben oder sich durch gleichmäßige Formen der Kurve (erzeugenden) Wand im gesamten Profil auszeichnen. Die Bauteile können viele verschiedene Arten von Löchern enthalten, z. B. Bohrungen, Senkbohrungen, Gewindebohrungen, gefrästes Loch usw.

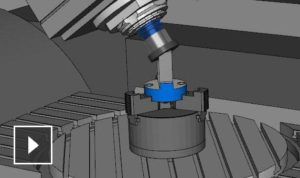

Die Funktion „2-Achs-Drehen“ ermöglicht eine schnelle und einfache Programmierung aller Arten von Drehteilen.

Diese Funktion in FeatureCAM ermöglicht die effiziente Nutzung des vollen Funktionsumfangs Ihrer Drehmaschine für eine schnellere und effektivere Produktion. Das leistungsstarke und dennoch einfach zu bedienende Modul enthält Feature Recognition (automatische Featureerkennung) und beschleunigt die Programmierung durch die automatische Auswahl geeigneter Werkzeuge und Einstellungen basierend auf der Geometrie Ihrer Werkstücke. Elemente können schnell und intuitiv gestaltet oder aus anderen CAD-Systemen importiert werden. Werkzeugwege sind vollständig mit den Elementen verknüpfbar. Falls eines ihrer Merkmale geändert wird, werden die zugehörigen G-Codes automatisch an diese Funktion angepasst. FeatureCAM verfügt über eine große Bibliothek standardisierter Gewinde, sowohl metrische als auch in Zoll, die die Programmierung erleichtern. Drehoperationen sind so programmiert, dass bereits bearbeitete Oberflächen nicht beschädigt werden können. FeatureCAM nutzt die unveränderlichen Bearbeitungszyklen vollständig, wodurch die Programmgröße reduziert und eine kürzestmögliche Bearbeitungszeit erreicht wird.

Die wichtigsten Funktionen der Drehbearbeitung sind:

- Bohrungen – gerade, Senkbohrungen, Spotter, Stufenbohrung, gerade Gewindebohrung, Stufengewinde – Möglichkeit zur Programmierung in konstanten Zyklen

- Drehen von Außenprofilen mittels einer 2D-Kurve

- Bohren von Innenprofilen mittels einer 2D-Kurve

- Einstechen/Vertiefungen mittels 2D-Kurve oder einem Assistenten

- Assistentengeführte Planbearbeitung

- Assistentengeführtes Trimmen mit Möglichkeit die Erfassung zu programmieren

- Drehen von Innen- / Außengewinden basierend auf einem Assistenten oder einer durch eine 2D-Kurve definierten Gewindekontur

- Handling der Stangenzufuhr

- Bedienung einer Gegenspindel und Möglichkeit der Programmierung unterschiedliche Erfassungsarten

Die Funktion „Drahterodieren“ in FeatureCAM erleichtert die Programmierung von 2- und 4-achsigen Drahterodiermaschinen. Die Bearbeitung kann basierend auf Volumenkörpern oder 2D-Kurven erzeugt werden. Die Materialbasis ermöglicht die automatische Kontrolle der Auswahl der Bearbeitungsparameter. Darüber hinaus besteht im Modul Funkenerosion die Möglichkeit, zwischen verschiedenen Arten der Drahteingabe in das bearbeitete Material zu wählen. Verschiedene Bearbeitungsstrategien sind ebenfalls verfügbar, z. Bsp. Schneiden mit Überbrückung erlauben und dann vollständiges Abschneiden eines Materials. Ausgehend von einer Werkstückgeometrie wählt das Modul Funkenerosion automatisch alle anwendbaren Einstellungen. Es ist für alle Arten von Drahterodiermaschinen geeignet. Die Funktion reduziert die Programmierzeiten und ermöglicht eine schnelle Produktion von qualitativ hochwertigen Teilen.

FeatureCAM mit Funkenerosionsbearbeitung ermöglicht folgende Operationen:

- Bearbeitung von Taschen

- Bearbeitung von Inseln

- Bearbeitung offener Vertiefungen

- Bearbeitung mit konstanter Drahtneigung

Typische Anwendungen für FeatureCAM sind die Herstellung von Getrieben, Elementen von Hydrauliksystemen oder Präzisionsventilteilen.

Vorteile:

- Automatische Auswahl von Operationen für verschiedene Frässtrategien

- Datenbank mit Schnittbedingungen, die Einstellungen für den Erodiergenerator, Spüleinstellungen und Werkzeugkompensation enthält

- Wird mit geprüften Postprozessoren für alle marktgängigen Maschinen geliefert, darunter unter anderem Agie-Charmilles, Fanuc, Mitsubishi und Sodick

- Es enthält eine vollständige Palette von Funktionen, die für die Erstellung von Bauteilen benötigt werden, einschließlich Matrizen, Stempel und Seiten

- Reduzierung der Programmierzeit aufgrund der vollständigen Personalisierung basierend auf den Vorlagen des Benutzers

- Vermeidung von Drahtbruch und daraus resultierenden Stillstandszeiten durch automatische Auswahl geeigneter Bearbeitungsparameter

- Verkürzung der Setup-Zeiten dank bewährter Postprozessoren für EDM-Maschinen, darunter Agie-Charmilles, Fanuc, Mitsubishi und Sodick

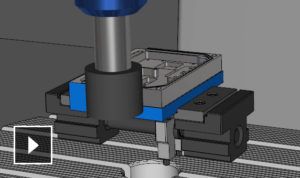

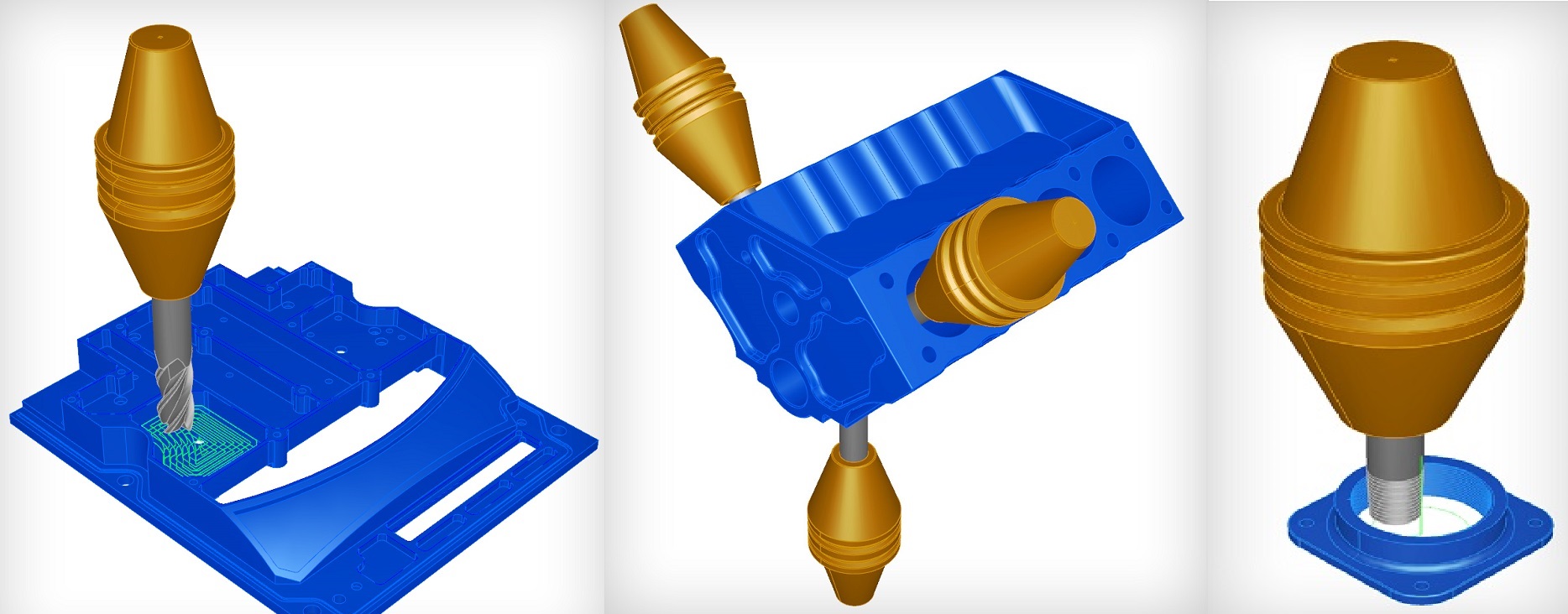

Das 3-Achsen-Fräsen in FeatureCAM Premium ist eine Komplettlösung für die 2D- und 3D-Bearbeitung, mit der selbst komplizierteste Teile hergestellt werden können. Es sorgt für enorme Möglichkeiten und Flexibilität. Diese Funktion enthält Frässtrategien, die auf denen von Autodesk PowerMill basieren, einschließlich Vortex – die Technologie, die es ermöglicht, die Bearbeitungszeit zu verkürzen und gleichzeitig die Spindellastamplitude zu minimieren und so die Werkzeugstandzeit zu erhöhen.

Das 3-Achs-Fräsen umfasst die volle Funktionalität des 2,5D-Fräsmoduls und der Feature-Erkennung und zusätzlich die einzigartige Funktionalität für die 3D-Oberflächenmodellierung. Dieses Modul ermöglicht das automatische Erkennen und Fräsen von freien 3D-Oberflächen (Schruppen, Vorschlichten und Schlichten) mit automatischer Auswahl der optimalen Werkzeuge (Kugelfräser). Es enthält viele weiterentwickelte Strategien, die sowohl die traditionelle Bearbeitung als auch die Hochgeschwinigkeitsbearbeitung unterstützen.

Vorteile:

- Extrem schnelle Entfernung von nicht benötigtem Metall, schnellere Produktion von Teilen

- Die geleichmäßige Belastung eines Werkzeugs erhöht die Standzeit des Werkzeugs

- Weniger plötzliche Änderungen der Schnittrichtung verhindert, dass Werkzeuge und Teile beschädigt werden

- Herstellung von Bauteilen mit ausgezeichneter Oberflächenqualität und folglich Verzicht auf manuelle Nachbearbeitung

Typische Anwendungen

- Einfache Werkzeuge – Formen, Stempel und Matrizen

- Bearbeitung von Gussteilen

Das 3-Achsen-Fräsen lädt native 3D-Modelle in den folgenden Formaten: Inventor, SolidWorks, SolidEdge, Parasolid, ACIS und 2D DXF / DWG.

Diese Funktion wird in vielen Bereichen häufig angewendet. Angefangen bei der Herstellung von Spritzgussformen oder Heißverformung bis hin zur Produktion von Teilen und Baugruppen für die Herstellung von Bauteilen und Prototypen. Viele Flugzeuge oder Automobilteile erfordern eine präzise Bearbeitung zahlreicher freier Oberflächen.

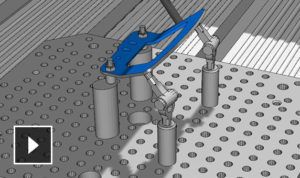

3+2-Fräsen in FeatureCAM Premium ermöglicht eine reibungslose Bearbeitung in 3 Achsen von verschiedenen Seiten und in einer einzigen Aufspannung. Die Anwendung von indexiertem 5-Achsen-Fräsen (3+2) erhöht die Produktivität senkt die Bearbeitungszeit. Es verringert oder beseitigt die Notwendigkeit einer Mehrfachpositionierung eines Werkstücks für seine vollständige Bearbeitung.

Vorteile:

- Reibungslose 2.5D-Bearbeitung durch automatische Berechnung der erforderlichen Anzahl von Umdrehungen und Transformation von Koordinatensystemen, um den Bearbeitungsprozess korrekt auszuführen.

- Volle Unterstützung für vertikale und horizontale Bearbeitungszentren.

- Erstellen eines NC-Codes unter Beibehaltung eines Koordinatensystems oder Erstellen eines neuen Systems für jede zu bearbeitende Oberfläche.

- Unterstützung für die vollständige 5-Seiten-Bearbeitung.

Wenn Sie ein 5-Achs-Bearbeitungszentrum mit Teilachsen haben, haben Sie die Möglichkeit, die Bearbeitung eines Teils gleichmäßig in 3 Achsen in einer Aufspannung durchzuführen. 3 + 2 Fräsen bedeutet in erster Linie:

- Vereinfachte Bearbeitung von tiefen Hohlräumen und Kernen,

- Verwendung von kürzeren Fräsern, Vereinfachung und Verbesserung der Oberflächenqualität,

- Weniger Einstellungen, wodurch Zeit und Geld gespart werden bei gleichzeitiger Eliminierung von Einstellungsfehlern,

- einfacher Zugang zu hinterschnittigen Bereichen.

FeatureCAM Premium kombiniert fortschrittliche Werkzeuge für anspruchsvolles und fortschrittliches Fräsen in 5 Achsen mit einer einfachen, intuitiven und benutzerfreundlichen Umgebung, die mit anderen Modulen des Programms in Einklang steht. Beschleunigt die Erstellung eines Werkzeugweges und gewährleistet gleichzeitig die volle Kontrolle über die Bearbeitung und die in Vorbereitung befindliche Werkzeugbahn.

Das Dreh/Fräs-Modul von FeatureCAM Premium ermöglicht die Fertigung von Bauteilen, die sowohl eine Dreh- als auch Fräsbearbeitung in einer Aufspannung erfordern.

Mit dem Modul bedienen Sie Ihre Dreh-Fräs-Maschinen. Es kombiniert die Fähigkeiten der Dreh- und 2.5D-Fräsmodule von FeatureCAM und ermöglicht es, Drehteile mit gefrästen Elementen zu fertigen. Die Funktion ermöglicht die Steuerung von C- und Y-Achsen sowie die Erzeugung von Fräsoperationen an der Haupt- als auch der Gegenspindel, um NC-Codes mit oder ohne Polar-Interlacing zu erzeugen. Fräsoperationen können mit Werkzeugen ausgeführt werden, die in der Z-Achse und in der X-Achse ausgerichtet sind. Dreh/Fräsen in FeatureCAM Premium bietet auch die Möglichkeit für Dreharbeiten mit Drehwerkzeugen. Die ist besonders effektiv bei der Bearbeitung von Bauteilen aus harten Materialien oder Bauteilen, deren Profil nicht kontinuierlich ist.

Dreh/Fräsen in FeatureCAM Premium ermöglicht:

- Erstellen von Drehoperationen, die im Modul Drehen aufgelistet sind,

- Erstellen von Fräsoperationen, die im 2.5D Fräsmodul aufgelistet sind,

- Durchführen von Fräsvorgängen an der Stirn- und an der Drehfläche eines gefertigten Werkstücks,

- Wickeln von 2D-Features auf einer rotierenden Oberfläche,

- Ansteuerung der C-und Y-Achse für beide Vorgänge an Haupt- als auch Gegenspindel,

- unterstützt polare Interpolation.

Vorteile:

- Dank der Unterstützung von Mehrspindelmaschinen mit C- und Y-Achsen und mit angetriebenen Werkzeugen können selbst komplexeste Bauteile bearbeitet werden,

- einfache Programmierung der Bohr- und Fräseigenschaften an der Stirn- oder Seitenfläche des Bauteils mit Hilfe des Feature-Assistenten für eine schnellere Bearbeitung,

- beinhaltet alle Funktionen von 2.5D-Fräsen, einschließlich Bohrungen, Nuten, Taschen, Seiten und Muster.

Typische Anwendungen:

- komplexe Bohrwerkzeuge für die Erdölindustrie,

- Kurbelwellen für Motoren.